I have a Taurus 740 Slim I wish I had an extended mag for (I know. . . taurus sucks, etc etc etc)

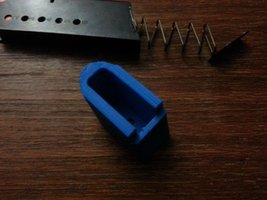

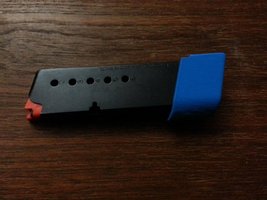

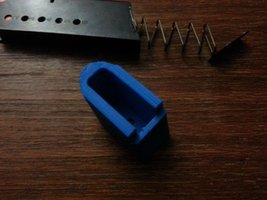

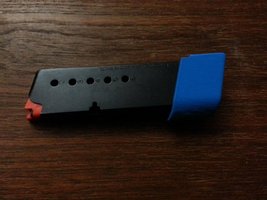

I measured the baseplate and extended it for +2 and VOILA!!!!!

Remember, It's okay if you keep under 10 rds (in this case it goes from 6 to 8).

If you have a preban over 10 rounds you can extend to infinity.

Buy a 3D printer now!

I measured the baseplate and extended it for +2 and VOILA!!!!!

Remember, It's okay if you keep under 10 rds (in this case it goes from 6 to 8).

If you have a preban over 10 rounds you can extend to infinity.

Buy a 3D printer now!