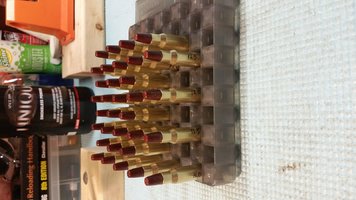

I have nor really figured out the best temp... last run I did not try to warm up the ignot mold and used laddle I found to fill them. The laddle fills a little light but thats ok.With Redneck Gold ingot molds on hand, I couldn't help myself so I mixed another 20lbs of 50/50 COWW and flashing lead.

Didn't wait long enough to get up to a high enough temp to get nice ingots but got to try them out.

Ingots came out at about 1kg and dropped out out the molds easily - @mac1911 thanks for setting up the buy on these, worth every dollar.

What do you run your smelting pot at?

Last edited: