I continue reading/watching and have a very noob question, i guess. in most articles it is somehow not truly covered.

if we go, for an example, based on this article - Finding the Sweet Spot

he speaks there about measuring with oal gauge, then playing with sitting depth from max of 2.820" down. i get it - it is not rocket science.

what i do not get - how does this process correlate or should be correlated with choosing the most optimal powder load amount?

So what i ask is this - should this seating process be repeated, essentially, from a scratch for an every different powder amount or powder/primer combination? or is the deviation caused by seating depth expected to be completely irrelevant from the amount or type of the powder used in the load?

i am trying to see how many parameters this game of chasing a single hole group has.

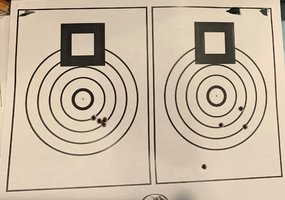

PS. speaking specifically of the groups in the article is it difficult to understand the first set of 2 groups - as one was tight and second was out of whack. and rest of groups also pretty much inconsistent. odd. but all i care of is to understand the approach to this routine.

if we go, for an example, based on this article - Finding the Sweet Spot

he speaks there about measuring with oal gauge, then playing with sitting depth from max of 2.820" down. i get it - it is not rocket science.

what i do not get - how does this process correlate or should be correlated with choosing the most optimal powder load amount?

So what i ask is this - should this seating process be repeated, essentially, from a scratch for an every different powder amount or powder/primer combination? or is the deviation caused by seating depth expected to be completely irrelevant from the amount or type of the powder used in the load?

i am trying to see how many parameters this game of chasing a single hole group has.

PS. speaking specifically of the groups in the article is it difficult to understand the first set of 2 groups - as one was tight and second was out of whack. and rest of groups also pretty much inconsistent. odd. but all i care of is to understand the approach to this routine.

Last edited: