-

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to reduce standard deviation?

- Thread starter paul73

- Start date

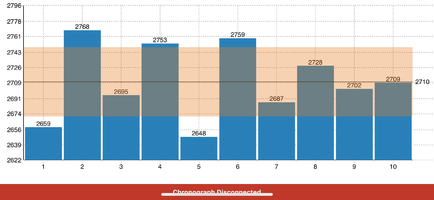

That was a set of 10 shots done at about 2 sec intervals. A 1 set of 14 I did today, some had much less max spread, some were comparable with this one. Powder measure weight was exactly same there - 23.4gn.You are only seeing a +/- 2% deviation.

How much time are you allowing the barrel to cool between shots?

Are you measuring OAL to the tip of the bullet, or are you measuring Ogive?

Just curious to know what else am I missing there, if anything. Last 4 shots were quite even.

Cases were from the same set, neck measured prior to priming, same sizing.

Last edited:

Cases were deviating in area of 3-4gn. Some were of exactly same weight.Did you weigh each bullet, each case, and each primer ? Consistency to that degree will make a difference....And how is the throat erosion in the chamber.

So, stupid question coming- how does case weight affect this? 100+ FPS speed diff?

I looked at bullets - they are identical, hornady eld 73gn, they seem to be uniform.

Yes?I’m not a PRS guy but how are the brass overall lengths? Need any trimming?

And I think you said in one of your other threads that your rifle is capable of 1/2 MOA groups with factory match ammo?

It is larue 20” .223. It can do half moa when it feels like it.Oh this is 223/5.56? Not 6.5CM?

TAC. Why does it matter?What's the powder?

I just try to understand what is the logic there for 5 shots to be almost same and other 5 to differ so much. Especially 2 slow ones

If you haven’t already, just for shits and giggles measure the brass and see if it needs to be trimmed. I have no idea if that would cause large SD’s?Yes?

It is larue 20” .223. It can do half moa when it feels like it.

BTSDOG

NES Member

Depending how much difference there is in case weight, the internal volume of the case could be more or less and the velocity could change due to the pressure increase or decrease caused by the difference in the internal volume of each case.....Cases were deviating in area of 3-4gn. Some were of exactly same weight.

So, stupid question coming- how does case weight affect this? 100+ FPS speed diff?

I looked at bullets - they are identical, hornady eld 73gn, they seem to be uniform.

It was trimmed and necks were set to same length. At least it measured same, within .002”, I spent some time on it. May be I missed somethingIf you haven’t already, just for shits and giggles measure the brass and see if it needs to be trimmed. I have no idea if that would cause large SD’s?

Dunno, I do not get it.Depending how much difference there is in case weight, the internal volume of the case could be more or less and the velocity could change due to the pressure increase or decrease caused by the difference in the internal volume of each case.....

Before powder measure drop each case was weighed and then confirmed to have precisely 23.4gn of powder in it, each.

I shot about of 50 factory rounds today, will try to process them all and load for next test. It got my interest. I will make sure now those f***ers are identical.

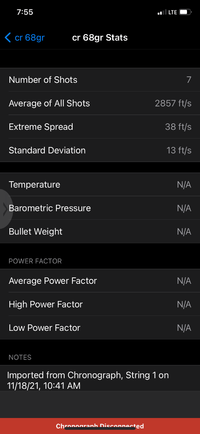

Factory set was clocked good. 38fps max diff. Mine was 120fps. It means I spoil something in the process.

Tallahassee

NES Member

Ball powder needs to fill the case for it to perform well. When I used TAC I was at 23.8, a little over mag length, had good results. This is a tough bullet to load for an AR.TAC. Why does it matter?

8208 is a better powder for this.

Sort by case weight, because that will affect volume.

Again, take note of my username and apply appropriate skepticism.Cases were deviating in area of 3-4gn. Some were of exactly same weight.

So, stupid question coming- how does case weight affect this? 100+ FPS speed diff?

I looked at bullets - they are identical, hornady eld 73gn, they seem to be uniform.

Loading .308 Win, I had similar ES issues with early loads using TAC and VV N150. I deliberately used only once fired Federal GM brass, Federal match primers. All cases were wet tumbled after depriming, primer pockets were uniformed, flash holes were uniformed/deburred, cases full length sized (bushing die), followed by mandrel expander to set 1 thousandth neck tension, trimmed, deburred/chamfered. Match grade bullets were sorted for weight AND length. Powder charges were weighed to within a hundredth of a grain (Matchmaster dispenser). Bullet runout measured at 5 ten thousandths or less. I.E., I got SILLY with making the loads consistent, and would STILL often measure a hundred FPS ES in a 10 shot batch (two 5 shot groups). I was only able to check target precision at 100 yards, because that's the longest range I had access to, but interestingly, 5-shot groups were all under .75 MOA despite ES (this might have resulted in much more vertical dispersion at longer ranges).

The last thing is changed was to add neck tension by changing the mandrel to give 2 thousandths neck tension. Same loads, etc. ES dropped to less than 15 FPS. Apparently in MY loads, there was insufficient neck tension and the bullets were starting to move out of the case inconsistently. Increasing neck tension solved it for me.

Different cartridge/powder/load/etc. compared to your situation, but thought I'd toss my experience into the ring. YMMV.

Tallahassee

NES Member

you are one step away from weighing and sorting primers!Again, take note of my username and apply appropriate skepticism.

Loading .308 Win, I had similar ES issues with early loads using TAC and VV N150. I deliberately used only once fired Federal GM brass, Federal match primers. All cases were wet tumbled after depriming, primer pockets were uniformed, flash holes were uniformed/deburred, cases full length sized (bushing die), followed by mandrel expander to set 1 thousandth neck tension, trimmed, deburred/chamfered. Match grade bullets were sorted for weight AND length. Powder charges were weighed to within a hundredth of a grain (Matchmaster dispenser). Bullet runout measured at 5 ten thousandths or less. I.E., I got SILLY with making the loads consistent, and would STILL often measure a hundred FPS ES in a 10 shot batch (two 5 shot groups). I was only able to check target precision at 100 yards, because that's the longest range I had access to, but interestingly, 5-shot groups were all under .75 MOA despite ES (this might have resulted in much more vertical dispersion at longer ranges).

The last thing is changed was to add neck tension by changing the mandrel to give 2 thousandths neck tension. Same loads, etc. ES dropped to less than 15 FPS. Apparently in MY loads, there was insufficient neck tension and the bullets were starting to move out of the case inconsistently. Increasing neck tension solved it for me.

Different cartridge/powder/load/etc. compared to your situation, but thought I'd toss my experience into the ring. YMMV.

Do NOT tempt me!!!you are one step away from weighing and sorting primers!

I still wait for type s die to come for .223, now it is way more than .002”, I know that. Or you mean, damn, I forget terminology- you mean shim for neck diameter or reducing neck length by .002” in an fl die?The last thing is changed was to add neck tension by changing the mandrel to give 2 thousandths neck tension

Paul,I still wait for type s die to come for .223, now it is way more than .002”, I know that. Or you mean, damn, I forget terminology- you mean shim for neck diameter or reducing neck length by .002” in an fl die?

No, I was experimenting with everything I could get my hands on to explore "precision" reloading. I noted discussions on PRS forums about techniques to enhance concentricity AND manage neck tension. Some professionals had started ADDING another die AFTER the sizing die to expand the case neck in a very controlled manner. They added a mandrel expander die with a replaceable mandrel that is much more concentric during neck expansion than and expander ball on a sizing die. To be fair, there is far more support for not using ANY expander when using the S type bushing dies (you can set the neck tension by changing the outside diameter of the case using those bushings. Again, I was exploring ALL possible approaches to precision loading.

In the situation I described, I resized cases with the bushing die and then expanded the necks with a mandrel expander die. The mandrel I used in the initial setting was exactly 1 thousandth less than the bullet diameter. The fix occurred when I changed to a mandrel that was 2 thousandths smaller than the bullet diameter.

Hope that's clear? Again, I was completely NUTS with everything I was doing, but it did allow me to isolate lots of variables. I don't routinely use the mandrel expanders after the bushing die anymore and still have good ES consistency after setting the appropriate neck tension with a smaller bushing.

Tallahassee

NES Member

Before you dive down the rabbit hole of precision reloading. I would try 8208 or varget, depending on your twist rate. I never got great results with TAC. I only use TAC for 55gr loads now.

I have a pound of varget if you would like to try that.

I have a pound of varget if you would like to try that.

I actually follow most of what you said.Paul,

No, I was experimenting with everything I could get my hands on to explore "precision" reloading. I noted discussions on PRS forums about techniques to enhance concentricity AND manage neck tension. Some professionals had started ADDING another die AFTER the sizing die to expand the case neck in a very controlled manner. They added a mandrel expander die with a replaceable mandrel that is much more concentric during neck expansion than and expander ball on a sizing die. To be fair, there is far more support for not using ANY expander when using the S type bushing dies (you can set the neck tension by changing the outside diameter of the case using those bushings. Again, I was exploring ALL possible approaches to precision loading.

In the situation I described, I resized cases with the bushing die and then expanded the necks with a mandrel expander die. The mandrel I used in the initial setting was exactly 1 thousandth less than the bullet diameter. The fix occurred when I changed to a mandrel that was 2 thousandths smaller than the bullet diameter.

Hope that's clear? Again, I was completely NUTS with everything I was doing, but it did allow me to isolate lots of variables. I don't routinely use the mandrel expanders after the bushing die anymore and still have good ES consistency after setting the appropriate neck tension with a smaller bushing.

One thing that bothers me - I highly doubt that creedmoore sports went over even remotely comparable sophistication for factory loads I was plinking today and they were much more consistent speed wise.

I wait for 8202 to arrive, varget is an unobtainium now online, I cannot scout stores.Before you dive down the rabbit hole of precision reloading. I would try 8208 or varget, depending on your twist rate. I never got great results with TAC. I only use TAC for 55gr loads now.

I have a pound of varget if you would like to try that.

TAC was easier to find so far. 8208 I saw only once and was lucky to get 2 cans only.

Yep, I want varget.

Last edited:

peterk123

NES Member

I would be thrilled with that. I believe if you are below 8% you are doing better than any ammo you can purchase.You are only seeing a +/- 2% deviation.

How much time are you allowing the barrel to cool between shots?

Are you measuring OAL to the tip of the bullet, or are you measuring Ogive?

- Joined

- Aug 8, 2009

- Messages

- 16,367

- Likes

- 4,835

I never had much luck with TAC powder or Hornady bullets when I shot service rifle. Reloader-15 and Sierra bullets were always my go-to. That said, +/- 60 fps is a .53 MOA spread at 300 if my calculator is right. People sometimes worry too much about stuff that the target doesn’t care about.

I am just puzzled as I cannot understand what did I miss.I would be thrilled with that. I believe if you are below 8% you are doing better than any ammo you can purchase.

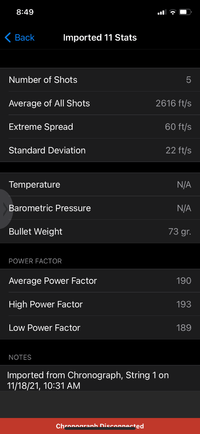

Here are 5 shots at 23gn load, same brass processed same way.

60 max spread. I would be ok and quiet if all batches were like that, but they are not. Yet I did same thing on all of them.

That bullet was a challenge. I want to try it with 8208 before either dumping it or just plinking it all at steel.I never had much luck with TAC powder or Hornady bullets when I shot service rifle. Reloader-15 and Sierra bullets were always my go-to. That said, +/- 60 fps is a .53 MOA spread at 300 if my calculator is right. People sometimes worry too much about stuff that the target doesn’t care about.

Here below best I could get today - those were 23 and 23.4gn loads, #11 and #12. Not close to what I want, but at least more consistent compared to other powders I tried so far.

Those 3 fast rounds in #12 stand out top right. Annoying.

That ES is high. People like to quote ballistics calculations for the velocity differences but that doesn't account for barrel dynamics and other issues.

Varget or Benchmark. I prefer Benchmark because it meters better and I have posted many sub 1/3 moa targets with it.

Unless your neck tension is awful, it's the powder.

Varget or Benchmark. I prefer Benchmark because it meters better and I have posted many sub 1/3 moa targets with it.

Unless your neck tension is awful, it's the powder.

Share:

Similar threads

- Replies

- 0

- Views

- 162

- Replies

- 4

- Views

- 135