TZCHRIS

NES Member

So I'm testing some new loads/new cast bullets. I am getting about 20% that wont gauge properly. See picts, they are very close but about .100" down from the crimp the case is bulging to .3805" dia. (compared to .3765 in good round) I used a black sharpie on one so you can see where the "bulge" is and where it hangs in the case gauge.

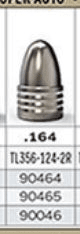

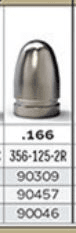

I case gauged all processed brass prior to loading and they are all fine, all projectiles were sized to .3555", I even double sized with same results. The COL is perfect on all finished rounds 1.125"

I tried to narrow it down to a specific head stamp to no avail? I even loaded just lead bullets (no powder coat) same results.......I'm at a loss, 20% is not acceptable! I just ran 3K 9mm with almost the same setup with just about 100% perfect results, the only difference was I used X-Treme factory bullets. I played with crimping, from zero to over crimp, same results. My only guess is maybe the bullet seating if not perfectly straight may force the case out? (picture below exaggerated so you get my point)

Any advice will be appreciated! Thanks, Chris

I case gauged all processed brass prior to loading and they are all fine, all projectiles were sized to .3555", I even double sized with same results. The COL is perfect on all finished rounds 1.125"

I tried to narrow it down to a specific head stamp to no avail? I even loaded just lead bullets (no powder coat) same results.......I'm at a loss, 20% is not acceptable! I just ran 3K 9mm with almost the same setup with just about 100% perfect results, the only difference was I used X-Treme factory bullets. I played with crimping, from zero to over crimp, same results. My only guess is maybe the bullet seating if not perfectly straight may force the case out? (picture below exaggerated so you get my point)

Any advice will be appreciated! Thanks, Chris