It’s like comparing an apple to a pc computer with an early version of Linux where every setting and driver needs to be configured manually. It’s a lot. Usually there are reference setups to use as starting points but nothing available for this unfortunately.

-

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

-

Be sure to enter the NES/MFS May Giveaway ***Canik METE SFX***

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D printing

- Thread starter NH Phantom

- Start date

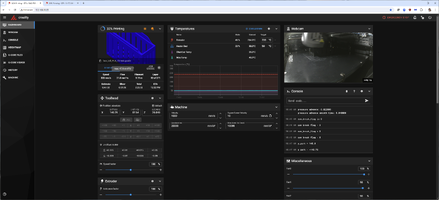

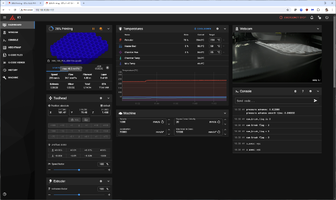

It’s running. What hung me up was an M83 command in my start print macro that sent the extruder into a tizzy every time it printed.

Wiring is a mess, I’m on my third Octopus Pro board, third z motor, and second extruder motor. Some of it is my fault due to very conflicting info online for pinouts, voltage, and config settings. Also think my x & y wires were way too long amongst the rats near of power wires.

But it’s printing at 2-300mm/s right now. I redesigned a few parts to fit my setup that need to be printed and installed. Once that is done I will start printing the electronics box so I can move all this crap out, organize the wires, and properly electronic things.

Now it is printing the chamber air filter that will also act as an exhaust fan.

On the immediate horizon: CAN bus, Tiny Fan board, CPAP cooling, and Beacon probe/bed scanner. That will allow me to run speed tests and tune the belts for faster speeds. One of the guys broke the 6 minute Benchy mark last night.

Then I start printing the new parts to accommodate the CR10 310mm bed that should come available in the next few weeks.

Wiring is a mess, I’m on my third Octopus Pro board, third z motor, and second extruder motor. Some of it is my fault due to very conflicting info online for pinouts, voltage, and config settings. Also think my x & y wires were way too long amongst the rats near of power wires.

But it’s printing at 2-300mm/s right now. I redesigned a few parts to fit my setup that need to be printed and installed. Once that is done I will start printing the electronics box so I can move all this crap out, organize the wires, and properly electronic things.

Now it is printing the chamber air filter that will also act as an exhaust fan.

On the immediate horizon: CAN bus, Tiny Fan board, CPAP cooling, and Beacon probe/bed scanner. That will allow me to run speed tests and tune the belts for faster speeds. One of the guys broke the 6 minute Benchy mark last night.

Then I start printing the new parts to accommodate the CR10 310mm bed that should come available in the next few weeks.

That's why there was a market for Dremel Digilab, and there is a market today for BambuLab X1.It’s like comparing an apple to a pc computer with an early version of Linux where every setting and driver needs to be configured manually. It’s a lot. Usually there are reference setups to use as starting points but nothing available for this unfortunately.

Some people, as unlikely as it seems, want their hobby to be printing stuff, not tinkering with recalcitrant FDM printers.

That's why there was a market for Dremel Digilab, and there is a market today for BambuLab X1.

Some people, as unlikely as it seems, want their hobby to be printing stuff, not tinkering with recalcitrant FDM printers.

Agreed. And I thought about that while doing this.

I could have easily bought a Bambu instead. I would have had to get rid of this bc there’s no space but I would have had a perfectly fine printer.

Perhaps I’m too stubborn for that, idk. I would absolutely have one as a second, reliable printer to print parts for the main beast.

so, i placed an ad for 2 my old bedslingers - which i had built to be improved versions of S1 creality printers, details are below:

www.northeastshooters.com

www.northeastshooters.com

if you want a problem free klipper run platform - it is what can get you right there into hi-temp printing solution.

WTS - 2 highly customized Ender 3 v2 printers, with camera and Klipper running on android. NO SHIPPING!!!

Hi, i am transitioning to k1 printers and want to sell my backup machines that were about $350 or so in total costs spent on they builds. Price is set firm at $200 per entire setup, as I can keep them anyway as backups, but run out of storage space. Both printers are in a perfect operational...

if you want a problem free klipper run platform - it is what can get you right there into hi-temp printing solution.

my k1 max is now perfected to run at 600mm/s and 1000 moving speed. shakes quite a bit when runs at that speed, but output is consistent.But it’s printing at 2-300mm/s right now.

nozzles now allow 48mm3/s. took some effort to make it work, but, it runs. and runs all klipper, full remote access, standard moonrake, love it.

frame would benefit from more rigidity, or course, i keep thinking of taking it apart but too lazy as it still does 95% of anything i want. the only big upgrade i did was install of the second cooling fan assembly on the opposite side from the stock fan, to mimic voron setup, and it made major difference in cooling.

Part cooling?

I need to add sheet cooling.

I need to add sheet cooling.

my k1 max is now perfected to run at 600mm/s and 1000 moving speed. shakes quite a bit when runs at that speed, but output is consistent.

nozzles now allow 48mm3/s. took some effort to make it work, but, it runs. and runs all klipper, full remote access, standard moonrake, love it.

frame would benefit from more rigidity, or course, i keep thinking of taking it apart but too lazy as it still does 95% of anything i want. the only big upgrade i did was install of the second cooling fan assembly on the opposite side from the stock fan, to mimic voron setup, and it made major difference in cooling.

Do you have a video you can post?

pastera

NES Member

Melting 48cc/s is insanemy k1 max is now perfected to run at 600mm/s and 1000 moving speed. shakes quite a bit when runs at that speed, but output is consistent.

nozzles now allow 48mm3/s. took some effort to make it work, but, it runs. and runs all klipper, full remote access, standard moonrake, love it.

frame would benefit from more rigidity, or course, i keep thinking of taking it apart but too lazy as it still does 95% of anything i want. the only big upgrade i did was install of the second cooling fan assembly on the opposite side from the stock fan, to mimic voron setup, and it made major difference in cooling.

Going with a farm to hit that level of production is much simpler and likely cheaper

Cht nozzles can do that. Operational issue becomes to cool that plastic fast enough and have a nozzle heating that can accommodate that flow for long extrusion. I usually try not to exceed 30-35 for a continuous fill, max flow above 45 works ok only in bursts around may be 2-3 inches of continuous extrusion.Melting 48cc/s is insane

Going with a farm to hit that level of production is much simpler and likely cheaper

There is an upgraded heater one guy sells that can fix it, but, I do not see a need.

Those extra high speeds work, though, ok, for simple models like trays and gaskets without a ton of corners and complicated geometry. For everything else it is a 300mm/s printer, which is also not too bad. I like it, and so far it works well. Plus it is rooted and runs standard moonrake. Klipper is still proprietary but it does not matter. All factory programs i simply disabled.

Last edited:

pastera

NES Member

I still need to brace and enclose my Tronxy so I can print PC and Nylon effectively.

Speed isn't in my top 3 factors (accuracy, first print success and reliability) but it's still a concern when print times reach or exceed a workday.

Speed isn't in my top 3 factors (accuracy, first print success and reliability) but it's still a concern when print times reach or exceed a workday.

each model has its own issues for sure. k1 max would benefit from additional rigidity on the frame big time, some folks dump an another $500-$800 into it making it essentially a voron but i am not inclined to do it at all. it is a decent 300mm/s universal printer that produces ok results on .20-.28 layers. and it is ok with me as is, for now.I still need to brace and enclose my Tronxy so I can print PC and Nylon effectively.

Speed isn't in my top 3 factors (accuracy, first print success and reliability) but it's still a concern when print times reach or exceed a workday.

k1 is now at the sale pricepoint of $425 - it is more or less adequate, k1 max is still a bit overpriced, but i still like it. not too many alternatives out there anyway, to choose from, that can run on a standard klipper with no factory imposed BS. it comes with its own gotchas and downsides, for sure, but, it mostly works, i would keep it at that. a person who knows what to do can make it work. as for a generic non-initiated user - going with a bambu labs is probably an easier path.

so, the k1 they had on sale came, as i wanted a spare for my k1 max - and, damn it, i won a lottery.

it has a shorted heater board, so power supply does not even start. will have to start now whole process with them.

original k1 max also had to be returned, originally, as extruder board died - but since i got a replacement, it was a champ.

but, creality strikes once again. i could not resist a $405 printer, and china gets her vengeance, again.

damn. be warned.

it has a shorted heater board, so power supply does not even start. will have to start now whole process with them.

original k1 max also had to be returned, originally, as extruder board died - but since i got a replacement, it was a champ.

but, creality strikes once again. i could not resist a $405 printer, and china gets her vengeance, again.

damn. be warned.

Last edited:

Not sure I’d buy a new Creality printer at this point

so, not gonna go into details,  , but i got it all resolved and it is up and running well.

, but i got it all resolved and it is up and running well.

an interesting part - k1 model now has same new nozzle design from k1c, and it seems to work decently fine on pla+, at least.

the fill-in in bursts goes up to 48, the wall print runs 28-35 and it prints fine.

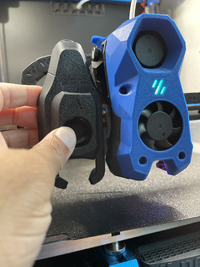

here is how new nozzles look like:

and here is where you get the script to install standard interface and remove all the creality OOB crap:

an interesting part - k1 model now has same new nozzle design from k1c, and it seems to work decently fine on pla+, at least.

the fill-in in bursts goes up to 48, the wall print runs 28-35 and it prints fine.

here is how new nozzles look like:

and here is where you get the script to install standard interface and remove all the creality OOB crap:

Last edited:

I moved all of my electronics out of the enclosure into an Omni box a forum member designed.

Before:

After:

Really loving that screen, makes control at the printer much easier.

I also added filtration and circulation for the enclosure; printing ABS & ASA is stinky.

Oh, and improved stepper cooling.

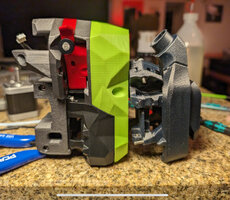

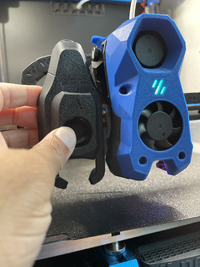

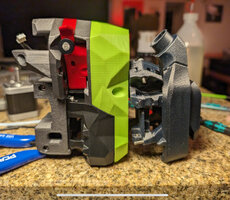

Swapping out my Stealthburner for Archetype.

The size comparison is absurd and cooling is much much better.

Before:

After:

Really loving that screen, makes control at the printer much easier.

I also added filtration and circulation for the enclosure; printing ABS & ASA is stinky.

Oh, and improved stepper cooling.

Swapping out my Stealthburner for Archetype.

The size comparison is absurd and cooling is much much better.

Next up is GT3 belt, supported stepper shafts, upgraded steppers, 5160 Pro drivers, upgraded rails, and a CR10 print bed. Oh and replacing the Mosquito hot block with NF-Crazy-Volcano.

Last edited:

Share: