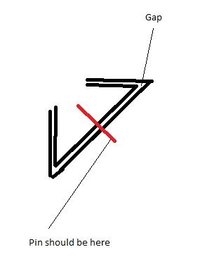

Having a problem with an m1a i bought recently. Trying to put a scope mount on it but I can't get the stripper clip guide out. The pin is missing, I can shine a light straight through the hole on top and can look through to confirm nothing in there. Easy, except the clip guide is on there like a ROCK. I've given it some pretty hard whacks with a mallet and even a hammer and it won't give an inch. What confounds me is that the gun came that way, bought brand new (so I think, from collectibles in NH).

Am I missing something?

Am I missing something?

Last edited:

![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif)