Golddiggie

NES Member

Google result that looks promising:

Last edited:

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

Be sure to enter the NES/Pioneer Valley Arms February Giveaway ***Smith & Wesson SD9VE 9MM***

I'm on travel but should be home late tomorrow and can talk you through odd thread sizes in Fusion once I'm sitting in front of my laptop.i have a very particular question, and would appreciate a hint, if anybody knows the exact answer, as i struggle to find a solution.

i am trying to make a coupler with a very specific thread - i need it to fit on a pipe that has 15/16"-24 thread.

i cannot find how to get such a nut of thread or anything in fusion 360. the only relatively close i see is under 'ansi unified screw threads' if you selct 0.9375 size - it gives options for some 15/16" threads - but it skips 24 - there is only 20 and 28.

and i cannot find any external script or utility to make such a thread, but, may be i am not looking right? i would usually pull it from a MaMaster-Carr catalog, but it does not seem to have a nut with such thread, which is quite odd. not sure wtf.

i have a very particular question, and would appreciate a hint, if anybody knows the exact answer, as i struggle to find a solution.

i am trying to make a coupler with a very specific thread - i need it to fit on a pipe that has 15/16"-24 thread.

i cannot find how to get such a nut of thread or anything in fusion 360. the only relatively close i see is under 'ansi unified screw threads' if you selct 0.9375 size - it gives options for some 15/16" threads - but it skips 24 - there is only 20 and 28.

and i cannot find any external script or utility to make such a thread, but, may be i am not looking right? i would usually pull it from a MaMaster-Carr catalog, but it does not seem to have a nut with such thread, which is quite odd. not sure wtf.

www.machiningdoctor.com

www.machiningdoctor.com

gotcha, will try, thx!

ThreaDoctor: Advanced Thread Calculator (UN, M, NPT)

The ThreaDoctor will calculste for you: Nominal thread data. Allowed tolerances depending on the thread class. and much more...www.machiningdoctor.com

You need to make a copy of ANSIUnifiedScrewThreads.xml and use the 15/16-20 as a template for 15/16-24 (both internal and external) you don't need to do the 3a/b tolerancing if you want to save some time.

Never said I was quick...

so...

ThreaDoctor: Advanced Thread Calculator (UN, M, NPT)

The ThreaDoctor will calculste for you: Nominal thread data. Allowed tolerances depending on the thread class. and much more...www.machiningdoctor.com

You need to make a copy of ANSIUnifiedScrewThreads.xml and use the 15/16-20 as a template for 15/16-24 (both internal and external) you don't need to do the 3a/b tolerancing if you want to save some time.

<Designation>

<ThreadDesignation>15/16-24 UNS</ThreadDesignation>

<CTD>15/16-24 UNS</CTD>

<TPI>24.0</TPI>

<Thread>

<Gender>external</Gender>

<Class>2A</Class>

<MajorDia>0.9362</MajorDia>

<PitchDia>0.9091</PitchDia>

<MinorDia>0.8866</MinorDia>

</Thread>

<Thread>

<Gender>internal</Gender>

<Class>2B</Class>

<MajorDia>0.9375</MajorDia>

<PitchDia>0.908</PitchDia>

<MinorDia>0.9158</MinorDia>

<TapDrill>0.8969 </TapDrill>

</Thread>

<Thread>

<Gender>external</Gender>

<Class>3A</Class>

<MajorDia>0.9375</MajorDia>

<PitchDia>0.9104</PitchDia>

<MinorDia>0.8879</MinorDia>

</Thread>

<Thread>

<Gender>internal</Gender>

<Class>3B</Class>

<MajorDia>0.9375</MajorDia>

<PitchDia>0.9145</PitchDia>

<MinorDia>0.8994</MinorDia>

<TapDrill>0.8969 </TapDrill>

</Thread>

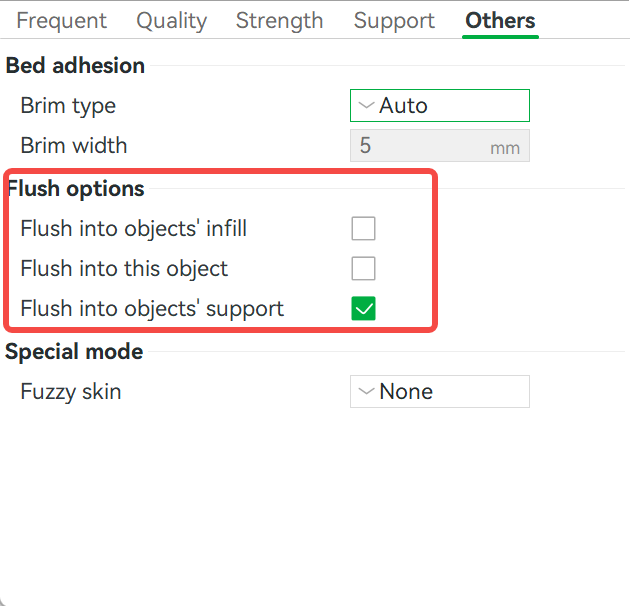

When you're just changing colors, one of the better options for the "flushed" filament at color change is to specify a flush object, something where you don't care what color it ends up being printed. Basically if you're printing a Yoda, then next to him on the printbed you add a powder funnel or something else where color doesn't matter (see screenshot below)]I have some things I want to design up that would be multi-colored

Manchester Makerspace has a Bambu X1 Carbon with the filament changer (AMS), if you want to see one working in person.I need to see about getting more info on how you use more than one filament in a print with their unit. I have some things I want to design up that would be multi-colored , or multiple filament types in the same print. I know that it ejects a decent amount of filament when you change during a print. Which means I'll probably need to position it someplace where I can setup a catch container for that. Shouldn't be too difficult to do where I would set it up.

You don'tso...

how do you deal with a, certain factor of shrinkage on the inner nut threads?

like, all printers i have are pretty well setup and correct external dimensions wise. if i print a bolt - it gets out fine, like those threaded dies i used for dillon.

but when a nut gets printed - its inner section is always a tad small, it would not get on a bolt with same thread, never. it would have to be re-printed with scaling it up, usully i do it in cura, for simplicity.

is there anything to address that in that construct above that you provided me? a scaling factor, may be, not sure.

Me going to the ManchVegas Makerspace wouldn't happen anytime soon. I'm not in a huge rush to get a new 3D printer though. At this point I need to wait for the job situation to stabilize (right now, even though I'm working, I have high levels of concern about the company not laying me off before end of year) before I make the purchase. The work situation has also put any largish purchases on hold.When you're just changing colors, one of the better options for the "flushed" filament at color change is to specify a flush object, something where you don't care what color it ends up being printed. Basically if you're printing a Yoda, then next to him on the printbed you add a powder funnel or something else where color doesn't matter (see screenshot below)

Manchester Makerspace has a Bambu X1 Carbon with the filament changer (AMS), if you want to see one working in person.

Depending on your object and filaments, there are options to reduce wasted filament:

plasticfantasticdeals.com

plasticfantasticdeals.com

If you're looking for "pretty" versus "functional" prints, consider going with resin.After following this thread for a while it seems interesting with a good amount of various applications. As with tech related items evolving quickly any recommendation for machines up to about $500 or so? Print quality is important.

we are now on the brink of major battle.After following this thread for a while it seems interesting with a good amount of various applications. As with tech related items evolving quickly any recommendation for machines up to about $500 or so? Print quality is important.

www.creality.com

www.creality.com

Ender 5 S1 ProAfter following this thread for a while it seems interesting with a good amount of various applications. As with tech related items evolving quickly any recommendation for machines up to about $500 or so? Print quality is important.

Concur with the Bambu - more expensive than the limit but opens up a large number of awesome accessories.If you're looking for "pretty" versus "functional" prints, consider going with resin.

If you want fine print quality and fast printing in ABS/PLA/PETG, save up the extra $200 and get a Bambu P1P

i would go with 3 S1 for this price:Ender 5 S1 Pro

Assemble and print, done

Print quality is a lot about filament quality and slicer settings/tradeoffs

If you do the assembly with care and then run a few tuning prints with a decent (doesn't need to be exotic) filament then the tradeoff becomes speed versus quality.

i would go with 3 S1 for this price:

View: https://www.reddit.com/r/3dprintingdeals/comments/146navf/260_ender_3_s1/

for how much?know someone who just bought a 5 S1 Pro.

I really need to standardize on one brand and stop getting whatever is in stock in the color I want. I'm at that point where quality trumps price. Who makes good, consistent PETG and PLA for under $50/kg?And remember cheap filament is only fine if you know what your doing so you can recognize issues and correct for them.

When starting out go for name brand filament in the $20-$25/kilo

$500 - the limit the OP set.for how much?

wat? $50?PLA for under $50/kg?

www.sunlu.com

www.sunlu.com

I use 3d Solutech followed by overture and Hatchbox the RepRapper.I really need to standardize on one brand and stop getting whatever is in stock in the color I want. I'm at that point where quality trumps price. Who makes good, consistent PETG and PLA for under $50/kg?

Thiswat? $50?

sunlu pla+ can be found on their web site at $11 per kg. jayo, sunlu, eSUN, polymaker, overture... amazon has quite a bit of options.

results for pla != pla meta != pla plus across brands, so test and stuck to what works for you.

to make it more fun they may change formulas from time to time and change how material works, as well.

comgrow right now has 1 refurbushed 5 s1 available for $319.$500 - the limit the OP set.

For a budget, I say get an Ender 3 and add the Sprite Pro along with a bed probe. That will get you to 3 S1 Pro level performance for less initial outlay.

But out of the box performance for someone who doesn't want to deal with a steep learning curve the 5 S1 pro gets you to nylon with the addition of a relatively cheap enclosure kit.

www.comgrow.com

www.comgrow.com

I really need to standardize on one brand and stop getting whatever is in stock in the color I want. I'm at that point where quality trumps price. Who makes good, consistent PETG and PLA for under $50/kg?

I really need to standardize on one brand and stop getting whatever is in stock in the color I want. I'm at that point where quality trumps price. Who makes good, consistent PETG and PLA for under $50/kg?