NH Phantom

NES Member

Looking for a loader. Not a holder

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

Be sure to enter the NES/Pioneer Valley Arms February Giveaway ***Smith & Wesson SD9VE 9MM***

Looking for a loader. Not a holder

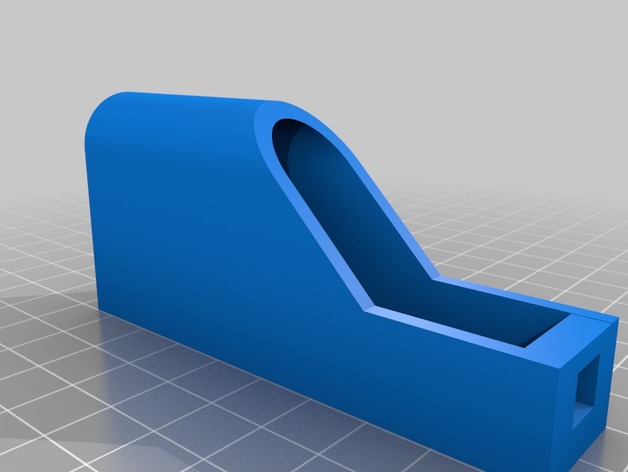

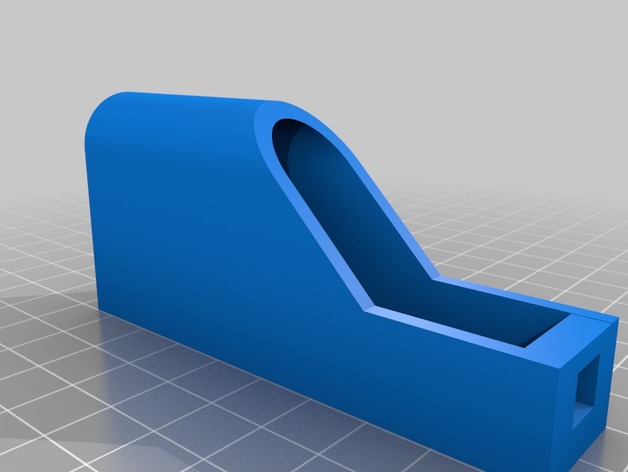

Ha, my bad, sorry. I’m 1/2 awake propped up in bed! I found this one online, seems like a straight forward design. I’ll play around with making something like this next week and report back. But before I march off do you have any ideas, designs, types you prefer?Looking for a loader. Not a holder

Thats exactly what I'm looking forHa, my bad, sorry. I’m 1/2 awake propped up in bed! I found this one online, seems like a straight forward design. I’ll play around with making something like this next week and report back. But before I march off do you have any ideas, designs, types you prefer?

I’ll play around with it next week and ping with results. I have a few different 1911 mags so I’ll be able to test as well.Thats exactly what I'm looking for

Large layer heights, slow speeds and high temps help a lot.Thats exactly what I'm looking for

Printing that one now. ThanksLarge layer heights, slow speeds and high temps help a lot.

You are looking at maximizing layer adhesion on the part that compresses the mag spring

I haven't tried this one but it is designed to try to address the issue

1911 Speed Loader .45ACP by GlowingEmbers

1911 Speedloader. Remixed into two pieces. As with the original, print the frame upside down.The press piece takes a lot of force and with the original, fails inevitably.Think about it, the only thing holding it to the frame is a single layer adhesion.By separating them and printing the press...www.thingiverse.com

Let me know how it works - I might model one up with a a flared base for a better gripPrinting that one now. Thanks

LOL I was just thinking this would be much better with a flared base!!Let me know how it works - I might model one up with a a flared base for a better grip

Slice with minimal infill, pause the print at appropriate times, pour in iron filings or play sand (Iron is preferred because you can clean it out of the printer with just a magnet)And since I’m on this thread. I finally printed a faux light and optic for my faux pew pew. You can even insert a mag into it. Fit is almost one to one. Feel is way way off as it’s so light, but it’s a just for fun print.

What plastic? One of the more exotic plastics might hold up better.A Friend of mine printed my some snap caps. The .22lr ones wear out the RI pretty fast.

I agree. I made some for a few people and the problem with the all plastic ones is that the extractor would crack the rims fairly quickly.What plastic? One of the more exotic plastics might hold up better.

Best option is the "insert" design, print the insert in Orange PETG, drop it into fired brass.

not sure, if you talk about PolyMide™ PA6-GF - i did read about it that is is not holding even 100deg C - deforms while boiling.The glass filled polymide from Polymaker was the strongest last I checked and they also have cf, depending what direction you want strength in.

Most of the cf nylon was too brittle and crap

some forums, probably on reddit most likely, a while ago. you think it`s BS?Where did you read that

some forums, probably on reddit most likely, a while ago. you think it`s BS?

so, any results? is it a bs or had material sagged?I will drop my Glock frame in boiling water and let you know. I think there’s a more than solid chance that is complete horse shit.

so, any results? is it a bs or had material sagged?

i am using for quite a while - 3 months - rooted k1 max that has standard klipper interface, slicing with orca - works amazingly well, and nothing proprietary needed at all.

Original Prusa 3D printers directly from Josef Prusa

Eshop by Prusa Research a.s., company founded by Josef Prusa, one of the RepRap core developers. We're selling Original Prusa 3D printers (incl. Prusa MK4, Prusa XL), filaments (especially our in-house made Prusament), resins, and other accessories for 3D printing.www.prusa3d.com

My next toy.

It's 14 inches high.Wow. That’s some darn good quality