I know nothing about klipper, Honestly, I don't know the difference between Klipper, Marlin, reprap, and if there are others. I know enough to follow directions on how to use and maintain my printers. So I don't know the benefits really

it is all about setting up pipeline and maintaining the 'factory'.

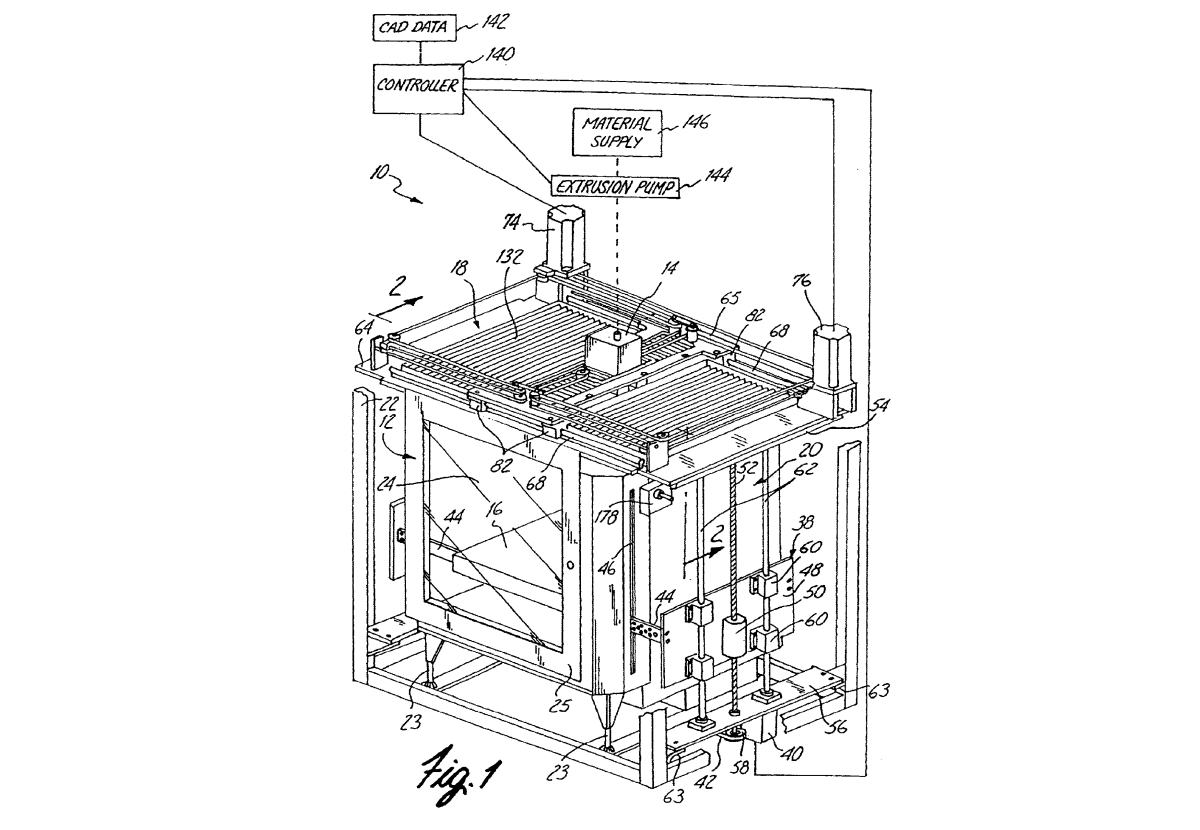

marlin is the firmware that runs inside of the printer itself. it is a printing engine, with no capabilities to maintain a library or do anything else at all - it only knows how to print and uses printers own mainboard and cpu to make all the decision of how to move the printing head. it was a huge limiting factor when those cpus were handicapped at 8 bit. it is a less of the limit now, as cpus were replaced with 32 bit models and got more power.

marlin has a decent community that supports the code base and improves it.

to maintain a library of models and have web interface to control the printer you need an external linux machine/box that can run octoprint - you will have a plugin for octoprint in the cure slicer - and can post model straight into the octoprint that will push it into the printer that is controlled by marlin

klipper takes it to a next level. accuracy and speed of printing even with 32bit CPUs is limited. klipper runs on a linux that is hosted on the external machine - your choice of what to use - like i use tv box, some your raspberry, or you can setup an intel/and real server to run multiple klippers on it -

so with klipper you essentially wipe out printer code completely and replace it with a klipper module that does nothing at all processing wise on the printer cpu - it only follows stream of external instructions that klipper generates on that poweful external cpu it uses.

so, getting to the point.

any commercial product today that is done by chinese uses a dumbed down stripped castrated snapshot of the community written marlin or klipper - now - with removed features and frozen in time for the time when they pulled the code. the community that supports and maintains both marlin and klipper makes huge leaps forward very fast compared to what bambu or creality can encapsulate into their firmwares.

with k1 it is espacially true, as the whole thing is pretty much a castrated combination of cura and klipper that creality locked and pushed a ton of adverts into. so, it is the reason behind of what i say - until someone finds a simple enough way to reuse their hardware witiout all of their software - it makes little sense to lock into that platform compared to what old platform can do.

the speed of evolution - how fast standard klipper gets new features and gets improved - it is really not worth doing anything else or deviate from it.