38ExtraSpecial

NES Member

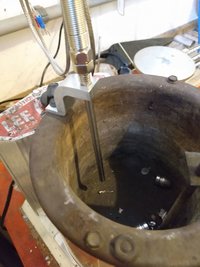

I like it!1st time reloading cast for my Savage 99 in 308. Barrel was slugged to .3085. Mold is a Lee C309-170-FN. Alloy of about 9-10 BHN (pencil hardness test), dropped at .309", 173gr. Three coats of candy apple red Hi Tek. Gas checked and sized to .309. Brass trimmed to 2.007 and expanded the neck just enough not to shave the bullet. Bullets seated to crimp groove. I was going to seat GC to neck base but GCs are on tight and figured I would start there. Light crimp (Lee collet). Started at 10gr of Unique and worked up to 12gr. Plan on testing on Monday.

View attachment 366616View attachment 366617