Jay77

NES Member

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

Be sure to enter the NES/MFS May Giveaway ***Canik METE SFX***

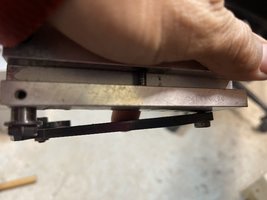

As long as will fit in the chamber.Dumb question…. When setting the depth is there a guideline on how deep to go with the cast bullets? Like past the last lube groove but before the ogive. These pictures might help with my question. The book says 1.68 max oal but that puts it in a lube groove. The longer bullet does chamber.

View attachment 581307

View attachment 581308

Figured I would ask. Going to load these up with 2400.

What mold is that?Dumb question…. When setting the depth is there a guideline on how deep to go with the cast bullets? Like past the last lube groove but before the ogive. These pictures might help with my question. The book says 1.68 max oal but that puts it in a lube groove. The longer bullet does chamber.

View attachment 581307

View attachment 581308

Figured I would ask. Going to load these up with 2400.

Any chance that the bullet is being forced in deeper during chambering? That could cause the case mouth tho shave some lead if it was crimped in too tight.It’s the lee 309 120 LH mold and the bullets are coated with hi-tek and sized to .311. I have to look around but I don’t think I have a .310. I have a .308 and .309 and I may have a .310 lube a matic die but I’ll have to look.

Photos so far are coming out like crap but I can say the bore is lead free and the lead shavings are in the chamber. That perfect lead ring was from a bullet that didn’t fully chamber and was ejected manually and the ring was on the un fired bullet. I’m going to try to take a run out tonight with the bullets I seated deeper.

Chamber casting would help .It’s the lee 309 120 LH mold and the bullets are coated with hi-tek and sized to .311. I have to look around but I don’t think I have a .310. I have a .308 and .309 and I may have a .310 lube a matic die but I’ll have to look.

Photos so far are coming out like crap but I can say the bore is lead free and the lead shavings are in the chamber. That perfect lead ring was from a bullet that didn’t fully chamber and was ejected manually and the ring was on the un fired bullet. I’m going to try to take a run out tonight with the bullets I seated deeper.

You need a bore scopeView attachment 583925

View attachment 583926

View attachment 583927

Patch one came with a small surprise…

This is where a chamber casting comes in handy. You see that ridge thats where the case mount “head spaces” against. Just forward is the lead/throat. Ideally the cast bullet should be sized to the lead or closeView attachment 583925

View attachment 583926

View attachment 583927

Patch one came with a small surprise…

Just be careful I bought a few cheap amazon bore scopes that said they worked with phones none have.I’ll drop the brass in the tumbler today, trim up the brass and size to .309 and see how it goes. A bore scope that connects to a phone would be handy.

Well the bullets look greatView attachment 586617

Had a nice session w my new mold from MP. The 6 cavity 9mm 147gr in brass.

22 lbs of production later, the RCBS promelt 2 is now officially clogged. Emptied the whole thing out and the tip is clogged w metallic substance. Propane torch doesn’t seem to be melting it. I hope some of you will have some suggestions. Murphy’s law, get new mold… now pot is acting up.

I had it running as high as 775 today and as low as 725. At 725 it wouldn’t take a new 1lb ingot without starting to loose viscosity, so I went back upwards and it ended up clogged after a while back at higher temps. I was able to keep unclogging it with a metal wire up the nozzle, but eventually even that wasn’t working so I ended up ladling it out and photos above is where I’m at now. Oh, the pleasures of casting

View attachment 586618

View attachment 586619

How do you like the brass vs. the aluminum?View attachment 586617

Had a nice session w my new mold from MP. The 6 cavity 9mm 147gr in brass.

22 lbs of production later, the RCBS promelt 2 is now officially clogged. Emptied the whole thing out and the tip is clogged w metallic substance. Propane torch doesn’t seem to be melting it. I hope some of you will have some suggestions. Murphy’s law, get new mold… now pot is acting up.

I had it running as high as 775 today and as low as 725. At 725 it wouldn’t take a new 1lb ingot without starting to loose viscosity, so I went back upwards and it ended up clogged after a while back at higher temps. I was able to keep unclogging it with a metal wire up the nozzle, but eventually even that wasn’t working so I ended up ladling it out and photos above is where I’m at now. Oh, the pleasures of casting

View attachment 586618

View attachment 586619

It’s hard to say… only 22lbs into them lolHow do you like the brass vs. the aluminum?

Helicoil?My other old aluminum 8 cavity is in serious need to repair. The bolt hole that holds on the sprue plate is stripped so I would like to retap the aluminum w a bigger threaded bolt. It’s a wierd bolt so i guess all I can do is hope MP carry’s a repair bolt that is the next thread size up.

Note the slop… can’t tighten bolt any further, the aluminum it’s in is stripped.

View attachment 586657

This - hit the nozzle with a torch, get it nice and hot (not glowing but hot) then clean out by twisting the drill bit by handWell the bullets look greatfind a drill bit that just seats in there and try to twist it by hand.

It’s probably a lot of oxidized junk.

It happens with the Lee pots too. Usually you don’t run them below 1/3 or 1/4 pot so you never let the floaty crud get to the spout.

Try to find a an even smaller drill bit that just fits into the bottom of the pour spout and do the same thing.

That’s why I run 2 moulds at a time. It’s keep the cadence perfect so you don’t overheat either mould. That is of course if you’re running similar sized moulds.It’s hard to say… only 22lbs into them lol

They were a little to frosty for my liking. I was trying to get the temp down to kill the frost and then the clogging started and kept getting worst.

My other old aluminum 8 cavity is in serious need to repair. The bolt hole that holds on the sprue plate is stripped so I would like to retap the aluminum w a bigger threaded bolt. It’s a wierd bolt so i guess all I can do is hope MP carry’s a repair bolt that is the next thread size up.

Note the slop… can’t tighten bolt any further, the aluminum it’s in is stripped.

View attachment 586657

Helicoil to the rescueIt’s hard to say… only 22lbs into them lol

They were a little to frosty for my liking. I was trying to get the temp down to kill the frost and then the clogging started and kept getting worst.

My other old aluminum 8 cavity is in serious need to repair. The bolt hole that holds on the sprue plate is stripped so I would like to retap the aluminum w a bigger threaded bolt. It’s a wierd bolt so i guess all I can do is hope MP carry’s a repair bolt that is the next thread size up.

Note the slop… can’t tighten bolt any further, the aluminum it’s in is stripped.

View attachment 586657